Stainless Steel

Ball Valves

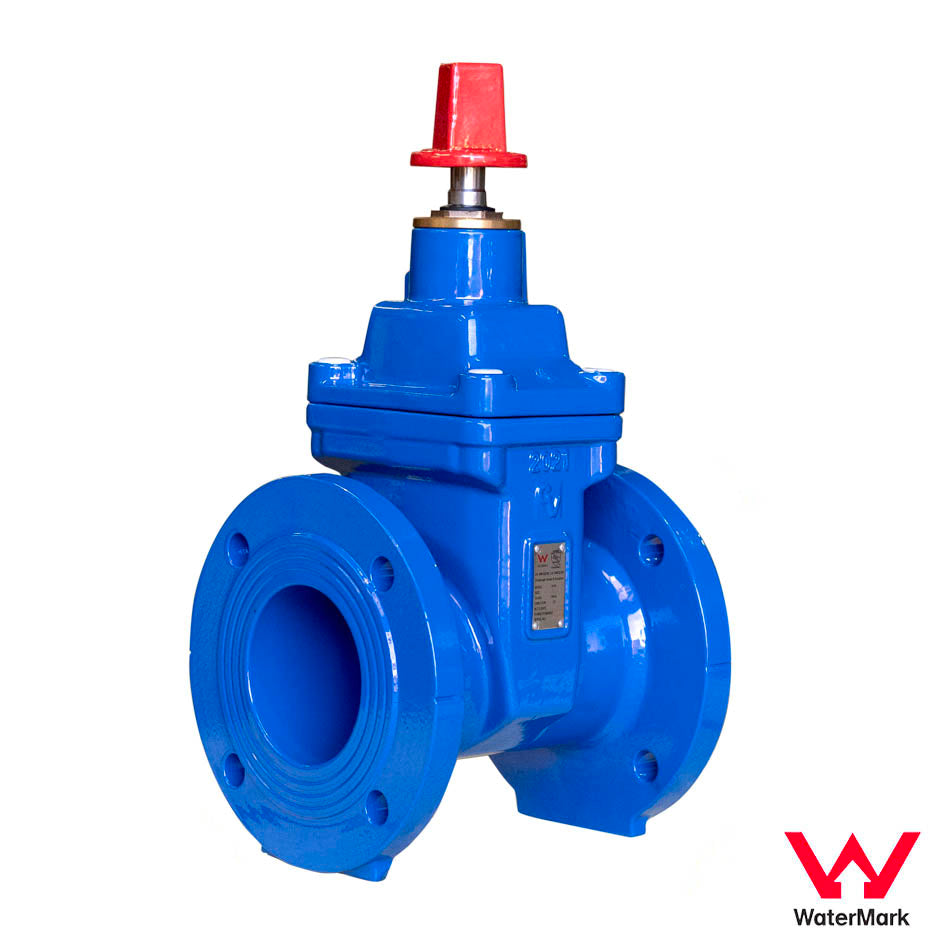

Stainless Steel Ball Valves are a popular type of valve used in a wide range of industries due to their durability, reliability, and versatility. These valves feature a ball-shaped disc with a hole in the center that rotates to control the flow of fluids or gases through the valve. The ball is supported by two seats, which ensures a tight seal when the valve is closed.One of the most significant advantages of stainless steel ball valves is their resistance to corrosion. Stainless steel is an alloy that contains chromium, which forms a passive film on the surface of the valve, preventing rust and corrosion. This makes them an ideal choice for use in harsh environments such as chemical processing plants, water treatment facilities, and offshore oil rigs.Stainless steel ball valves also offer excellent temperature and pressure resistance, making them suitable for use in high-temperature and high-pressure applications. They can withstand temperatures ranging from -50°C to 200°C, and pressures up to 1000 bar, depending on the size and type of valve.Another advantage of stainless steel ball valves is their ease of maintenance. They are simple in design, with few moving parts, and can be easily disassembled for cleaning or repairs. This reduces downtime and maintenance costs, making them a cost-effective solution for many applications.Stainless steel ball valves are available in various types, including full port and reduced port valves. Full port valves have a larger opening, allowing for higher flow rates and reduced pressure drops, while reduced port valves have a smaller opening, making them more suitable for precise control applications.In summary, stainless steel ball valves are a reliable and efficient solution for controlling the flow of fluids and gases in a wide range of industries. Their corrosion resistance, temperature and pressure resistance, ease of maintenance, and various types make them a versatile choice for many applications. Choose stainless steel ball valves from Challenger Valves for superior quality and performance.

Video Overview

Stainless Steel Ball Valves

Ball Valves

Ball Valve - SS2006S

Ball Valve - SS2013N

Ball Valve - SS2013ND

Ball Valve - SSRV2

Ball Valve - SS2020D

Ball Valve - SS2057D

Ball Valve - SS2017K

Ball Valve - SS2057N

Ball Valve - SS2013KMD

FAQ

What are stainless steel ball valves?

Stainless steel ball valves are types of mechanical devices that control the flow of fluid or gas by means of a rotating ball that has a bore. The stainless steel material makes them resistant to corrosion and high temperatures, ensuring a long-lasting and efficient operation in various industrial applications.

In what applications are stainless steel ball valves commonly used?

Stainless steel ball valves are commonly used in a variety of applications including water supply systems, oil and gas industries, chemical processing industries, food and beverage industries, and pharmaceuticals. They are ideal for applications where corrosive or high-temperature fluids are involved, and where sanitation is necessary.

How does a stainless steel ball valve work?

A stainless steel ball valve works by utilizing a handle that turns a ball inside the valve body. This ball has a hole or bore through its center. When the bore aligns with the pipeline, it allows flow; when it's perpendicular to the pipeline, it blocks flow. Turning the handle 90 degrees opens or closes the valve.

How do I maintain a stainless steel ball valve?

While stainless steel ball valves are known for their durability, regular inspection and maintenance can extend their life. This may involve routine checks for leaks or damage, regular cleaning, and occasional replacement of worn parts. Some types may require lubrication. Always refer to the manufacturer's guidelines for specific maintenance procedures.

Are stainless steel ball valves better than those made from other materials?

The choice of valve material depends on the specific application. Stainless steel ball valves are often favored for their high corrosion resistance and temperature tolerance, making them suitable for harsh environments. However, they may not be necessary for less demanding applications where a lower-cost material, such as brass or PVC, would be adequate. Always consider factors like the nature of the fluid, operating temperature, pressure, and the overall system requirements when selecting a valve.