Preventative Maintenance Tips for Industrial Valves and Expansion Joints

News

Learn essential preventative maintenance practices for valves and expansion joints, ensuring optimal performance, extended lifespan, and reduced downtime in your systems.

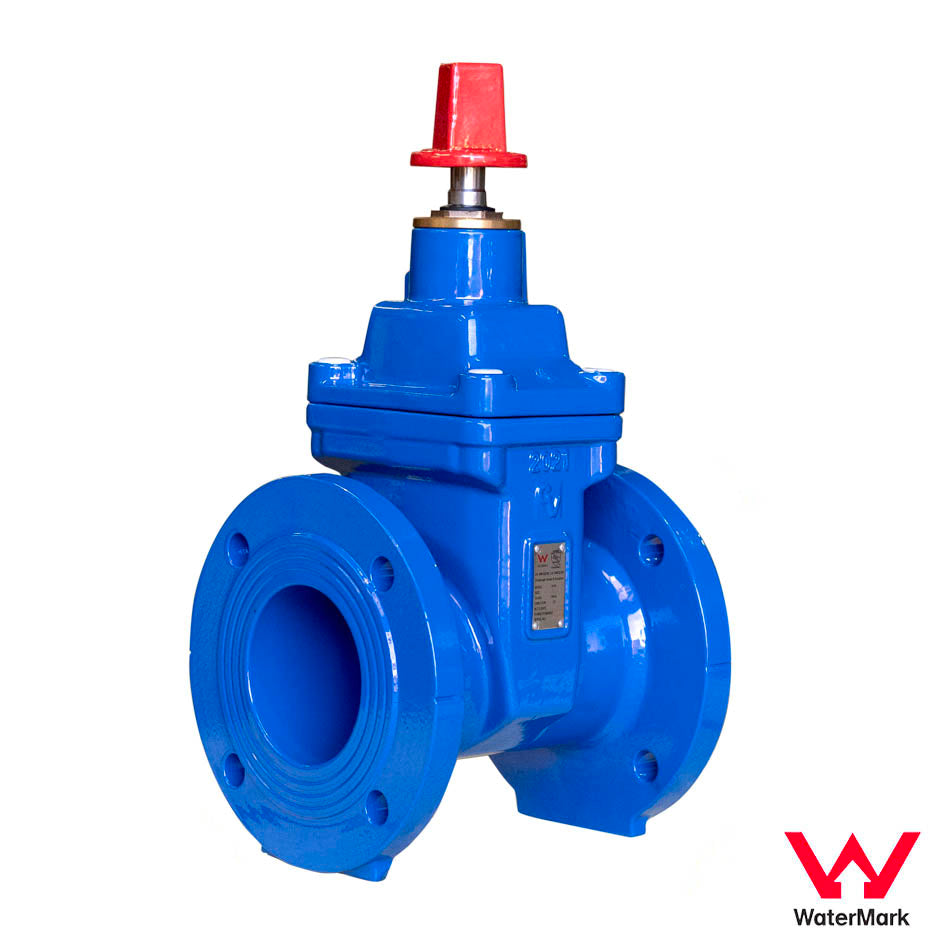

Industrial valves and expansion joints play a crucial role in maintaining the efficiency and reliability of various processes across numerous industries. To ensure their optimal performance and longevity, it is vital to implement a well-planned preventative maintenance program. In this blog post, we will discuss essential maintenance tips for industrial valves and expansion joints that can help reduce downtime and extend their service life.

-

Regular Inspection and Monitoring A crucial aspect of preventative maintenance is the regular inspection and monitoring of valves and expansion joints. Establish a schedule for visual inspections, looking for signs of wear, damage, or leakage. Monitor the operating conditions, such as pressure, temperature, and flow rate, and compare them with the manufacturer's specifications to ensure the system is functioning correctly. Additionally, consider incorporating sensors and IoT devices to enable real-time monitoring and facilitate timely interventions.

-

Lubrication and Cleaning Proper lubrication is vital to maintain the smooth operation of valve components and prevent excessive wear. Ensure that all moving parts are adequately lubricated according to the manufacturer's recommendations, and use the appropriate lubricants for your specific application. Regular cleaning is also essential to prevent the buildup of debris or contaminants that can hinder valve performance. Implement a routine cleaning schedule and ensure that all components are cleaned and free of obstructions.

-

Valve and Expansion Joint Alignment Misalignment of valves and expansion joints can result in increased stress on piping systems and cause premature failure. Regularly check the alignment of your valves and expansion joints, and make necessary adjustments to maintain proper positioning. When installing new components, follow the manufacturer's guidelines for alignment to ensure optimal performance.

-

Seal and Gasket Replacement Seals and gaskets are critical components that help prevent leakage and maintain the integrity of your valve and expansion joint assemblies. Over time, these components can wear out and lose their effectiveness. Establish a schedule for inspecting and replacing seals and gaskets based on the manufacturer's recommendations, or as needed based on observed wear or leakage.

-

Documentation and Record Keeping Maintaining accurate records of maintenance activities and the performance history of your valves and expansion joints is essential for effective preventative maintenance. Document all inspections, repairs, and replacements, and use this information to identify trends or recurring issues that may require further investigation or intervention. This data can also help you make informed decisions regarding future maintenance activities and system upgrades.

In conclusion, implementing a comprehensive preventative maintenance program for your industrial valves and expansion joints is crucial to ensure their optimal performance, extended lifespan, and reduced downtime. By following these essential maintenance tips and adhering to manufacturer guidelines, you can safeguard the efficiency and reliability of your systems and minimize the risk of costly failures and disruptions.